San Antonio homeowners face a unique climate rhythm, warm afternoons, cool evenings, and the occasional sharp cold front. Because of that, the furnace must stay ready to respond to sudden temperature swings. When it stops working efficiently, repairs quickly move from an inconvenience to a priority. Understanding the factors that influence furnace repair in San Antonio helps homeowners make informed decisions before scheduling service.

This guide breaks down the average heating repair costs, common issues, cost ranges, and the key factors that shape furnace repair pricing in Texas.

What Determines Furnace Repair Costs in San Antonio?

The first step in understanding furnace repair in San Antonio pricing is knowing what actually drives the bill. Most homeowners see wide price variations because every repair involves different parts, system types, and labor levels.

That’s where cost factors for furnace repairs come in. Once these factors are clear, estimates make more sense and unexpected charges become less of a surprise.

Here’s what really shapes repair costs in Texas:

1. The Type of Furnace System

San Antonio homes rely on a mix of furnace styles. Each one reacts differently to repairs, and some take longer to diagnose.

-

Gas Furnaces

These are most common in Texas. They offer strong heat output but involve several components: burner assembly, gas valves, ignitors, and heat exchangers. Repairs usually cost more because gas systems require more safety checks. Many of the repair cost differences also reflect broader differences between electric vs gas heating systems, since each operates under different demands.

-

Electric Furnaces

These are simpler, and repairs tend to cost less. Without the need for gas line inspections or combustion-related testing, most issues fall on the lower end of average heating repair prices. Their straightforward electrical components also speed diagnostic work, keeping overall service costs more manageable.

-

High-Efficiency Furnaces

These systems save money on monthly bills but require complex components such as secondary heat exchangers, ECM blower motors, and control boards. Repairs cost more, and labor time increases.

2. The Severity of the Problem

Minor issues like thermostat miscommunication or loose wires stay on the cheaper side. Major failures, heat exchangers, blower motors, and cracked ignitors quickly raise repair costs. Here’s a cost breakdown:

| Repair Type | Typical Cost Range |

| Thermostat recalibration | Low |

| Sensor cleaning | Low |

| Burner repair | Moderate |

| Blower motor replacement | Higher |

| Heat exchanger issues | Highest |

3. The Timing of the Service Call

Late-night failures, weekend breakdowns, or repairs during the first cold snap often come with higher labor charges. This is where emergency furnace repair costs become relevant. Emergency calls cost more than standard visits due to technician availability, workload, and the need for urgent scheduling.

-

After-Hours Repairs

Late-night failures and weekend breakdowns require emergency scheduling. Technicians adjust their availability, and the added demand increases the labor charge.

-

Seasonal Demand

The first cold snap of winter causes a surge in furnace failures across San Antonio. When demand spikes, companies raise prices because technicians are booked around the clock and replacement parts move quickly.

-

Urgent Appointments

Same-day and priority appointments cost more simply because they require technicians to rearrange their schedule to handle the heating emergency immediately.

4. Labor Rates in the San Antonio Area

Labor add on a significant amount in any furnace repair bill. Rates vary across the region based on experience, company reputation, and job complexity. These labor variations become easier to understand when you break them down into the main factors that influence overall service pricing.

-

Standard Labor Charges

Most HVAC companies follow an hourly model that reflects technician experience, overhead, and seasonal workload. Jobs that require minimal testing stay within a standard price range.

-

Diagnostic Time

Some furnace problems reveal themselves quickly. Others require step-by-step testing of sensors, wiring, airflow, ignition, and circuitry. The longer the diagnostic process, the higher the labor portion of the bill.

-

Specialized Skill Requirements

Modern high-efficiency furnaces and smart thermostats require technicians with advanced training. When specialized knowledge is needed, labor costs increase.

5. Availability of Replacement Parts

Part shortages during high-demand seasons can delay repairs and push prices higher as suppliers work to restock essential components. In some cases, technicians must source parts from out-of-state distributors, which adds both time and additional cost to the final repair. These differences in availability become even clearer when looking at the types of parts commonly used in furnace repairs.

-

Standard Components

If the furnace uses widely available components such as universal ignitors or standard sensors, repair pricing stays manageable. These parts are easy for suppliers to stock and quick for technicians to replace.

-

Brand-Specific Parts

High-efficiency and premium systems often use proprietary components. These parts cost more and may need to be sourced from the manufacturer, which increases cost and repair time.

-

Older or Discontinued Units

When a furnace model is discontinued, compatible parts become harder to find. Repair companies may need to order from specialty suppliers, which can raise both parts and labor costs.

6. Seasonal Conditions in San Antonio

Sharp temperature swings can strain older furnaces, causing sudden failures that drive up service requests across the city. As demand rises, homeowners often face longer wait times and higher repair costs until conditions stabilize. These seasonal shifts affect furnace performance in several noticeable ways:

-

Winter Surge

The first cold spell triggers widespread furnace use. As systems wake up from months of inactivity, many fail, leading to a surge in service calls and higher repair costs.

-

Mild-Season Repairs

Homeowners who schedule furnace service during mild weather typically benefit from lower wait times and more stable pricing.

-

Storm-Related Failures

Power surges, humidity spikes, and sudden temperature drops can stress internal components, causing unexpected failures that require immediate attention.

7. Warranty Coverage

Warranties also give homeowners access to approved replacement parts, which helps avoid unexpected price increases during repairs. Without coverage, even minor component failures can become costly, especially when both parts and labor must be paid out of pocket. Here’s how different types of warranties impact repair costs.

-

Manufacturer Warranty

This typically covers major components for several years. When covered, homeowners pay labor only, not parts.

-

Extended Warranty

Extended coverage can reduce the cost of long-term ownership by covering both parts and labor for larger failures.

-

No Warranty

When the furnace is outside of warranty, the homeowner covers the full cost of diagnostics, labor, and replacement parts.

8. Age and Condition of the Furnace

A furnace’s age plays a significant role in how expensive repairs become. Older equipment has more internal wear, which often leads to deeper failures. This aging process shows up in several key areas that directly influence repair difficulty and cost, such as the following.

-

Wear and Tear Over Time

As furnaces age, motors slow down, sensors corrode, heat exchangers weaken, and wiring connections loosen. These issues require more time to troubleshoot and more parts to replace.

-

Maintenance History

A furnace that receives regular tune-ups is easier and cheaper to repair. Units that go years without maintenance typically have clogged burners, dirty sensors, airflow problems, and electrical failures, all of which drive repair costs upward.

-

Approaching End-of-Life

Once a furnace reaches 15 to 20 years of age, repair costs rise because components begin to fail more frequently. Technicians may recommend comparing the repair price against the cost of a replacement.

Conclusion!

Understanding the factors that affect furnace repair prices in San Antonio gives homeowners a more straightforward path to making smart, confident decisions when something goes wrong. Once you know how these pieces work together, it becomes easier to recognize fair pricing, plan for it, and avoid unnecessary stress during a breakdown.

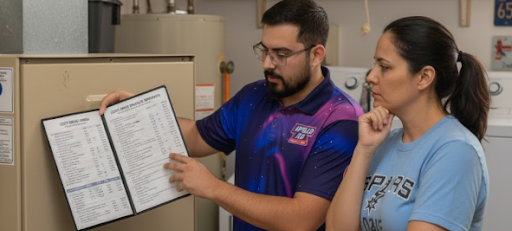

When the heat cuts out, and comfort becomes a priority, having a trusted HVAC Contractor in San Antonio, TX makes all the difference. Apollo Air Heating & Cooling brings the experience, fast response, and honest guidance that homeowners rely on. Whether it’s HVAC repair in San Antonio, TX, or warranty services, you can depend on us to keep your home comfortable. Trust us for out-of-this-world service that puts you first.

Contact our furnace repair experts at Apollo Air Heating & Cooling today and restore comfort to your home with confidence.